A week on board Fugro Symphony

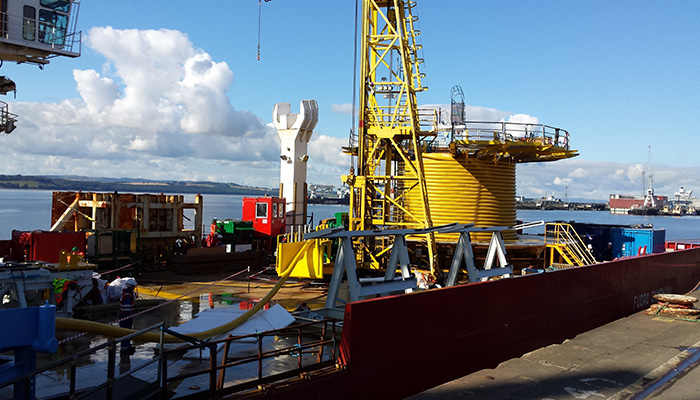

Day 1: The vessel sails for umbilical manufacturer Oceaneering Umbilical Solutions following a week of installation equipment mobilisation. Fugro Symphony is now equipped with carousel, spooling tower with tensioner and vertical lay system.

Day 2: The umbilical end termination (UET) was moved towards the quayside prior to vessel arrival. The umbilical transpooling could actually start once the UET was lifted and secured onto the carousel roof.

Day 3: The transpooling of the 5300meters long umbilical was completed and the second UET was lifted onto the vessel. Two mudmats, which will serve as foundations for the UETs on the seabed for the next 25 years.

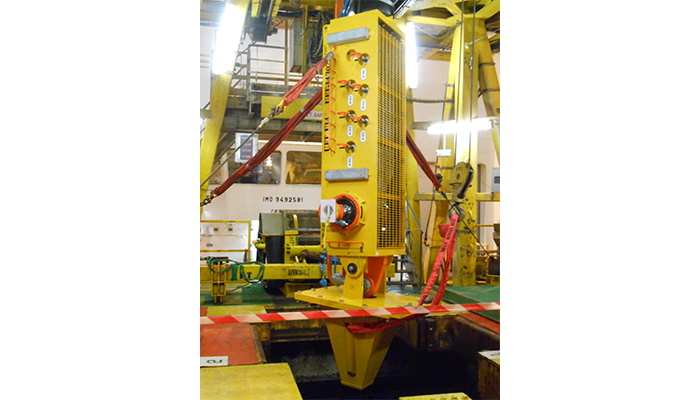

Day 4: Transit from Rosyth to Lerwick on the Shetland Islands. The lifting of the UET into the vertical lay system does take place here via a combination lift of onshore crane and vessel crane. The lift will go to height of 40 meters.

Day 5: Sail from Lerwick to the installation location of Quad 204. The preparation operations include a pre-installation survey, route clearance, placement of mudmat and initiation clump weight. Umbilical installation commences when the UET is lowered through the vessel moonpool.

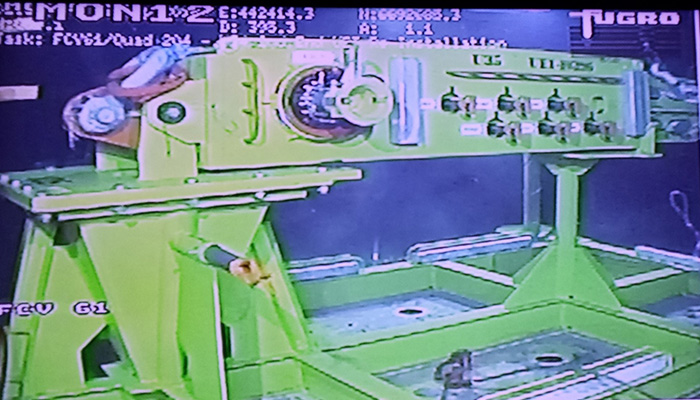

Day 6: The UET is landed on the mudmat and umbilical lay commences away from the drill centre towards the FPSO location. A remotely operated vehicle (ROV) conducts touch-down monitoring to ensure umbilical is positioned in right location.

Day 7: The umbilical installation campaign is completed once the UET is placed on its mudmat and a post-installation survey of the entire route has been completed. Fugro Symphony sets sail away from the field towards Rosyth for collection of the second umbilical.

About us

Who is LARSoffshore?

LARSoffshore is a privately-owned independent company and was established early 2013. LARS stands for Lease And Rental Solutions. Our aim is to deliver effective, innovative, quality and reliable specialist solutions to the offshore oil & gas and offshore renewables industries. LARSoffshore founders, as true engineers at heart, love to be involved with challenging projects worldwide. Our playground ranges from shore approaches via subsea installation, pull-ins to offshore connections and tie-ins, while our engineering solutions include installation & seafastening analysis, installation & field engineering, burial assessments & route engineering, method statements and procedures.

What do we make?

LARSoffshore provides Lease And Rental Solutions to the worldwide offshore oil & gas and offshore renewables industries. Our hardware solutions include carousels, chutes, reels, reel drive systems, tensioners, turntables amongst other required installation aids for projects involving flexibles, electrical or hydraulic flying leads, jumpers, pipelines, risers, structures, umbilicals or any other project product. Our personnel can assist with mobilisation & installation assistance or any support requested to any project worldwide. We work in accordance to QHSE management standards ISO 9001, ISO 14001 and OHSAS 18001.

People behind LARSoffshore

Gerard Kroese

Founder

Gerard Kroese is Director of LARSOffshore. In this role, Kroese manages day-to-day aspects of the business and our projects. He is currently involved with an offshore oil & gas field development in the West of Shetland-area and the development of our installation equipment.

He has held several project management positions at leading offshore subsea and construction companies Allseas, Cecon and Subsea 7 prior to founding LARSOffshore. He was co-founder and Director of Projects at successful start-up Blue Offshore. He has been involved with offshore cable, pipelines, umbilicals and vessel conversion projects for close to 20 years.

Kroese holds a BSc-degree in civil engineering from The Hague University (NL) and an MBA from the University of Durham (UK).

Kroese is married and has three sons.

Our work

BP QUAD 204 IS AN AMBITIOUS PROJECT

The Quad 204 project is an ambitious project and involves a major re-development of the Schiehallion and Loyal oil fields to the west of the Shetland Islands. The investment of circa £3 billion in the re-development of the fields will take production out to 2035 and possibly beyond.

The project involves construction of a new floating, production, storage and offloading (FPSO) unit toreplace the Schiehallion FPSO at the West of Shetland Islands. The new FPSO, called Glen Lyon, will be 270 metres long by 52 metres wide and able to process and export up to 130,000 barrels per day of oil and store in excess of 1 million barrels.

There will also be a major investment in upgrading and replacement of the existing subsea system with 15 new and replacement flow lines and 21 new and replacement risers. With the addition of 14 new wells to the 52 existing ones, one could argue that it’s a big job!

Although the field has been in operation since 1998, recent appraisals show that the field holds more reserves than originally anticipated and this redevelopment will give BP and their partners the ability to reach them. The FPSO and its subsea structures will be installed in modules with production to commence in 2016.

LARSoffshore is involved with umbilical installation for the Quad 204 project.

NORTHWIND EXPORT CABLE

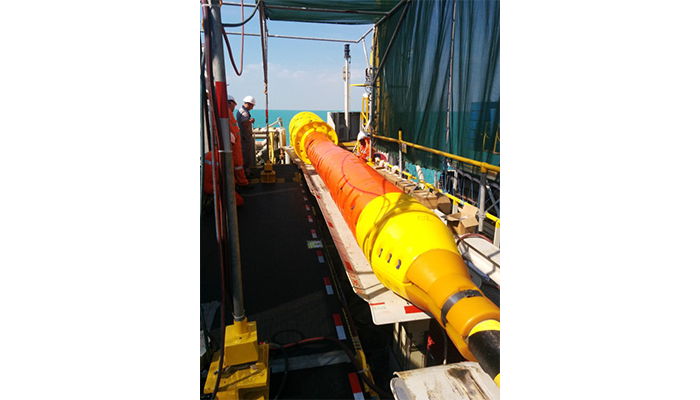

LARSoffshore was involved with the Northwind export cable and Belwind 2 interconnector cable. The 43.3km long 245kV three-phase Northwind export cable does connect offshore high voltage sub-station with the onshore grid. The 14km long 245kV three-phase Belwind 2 interconnector cable does connect Belwind 2 offshore high voltage sub-station with Northwind offshore high voltage sub-station.

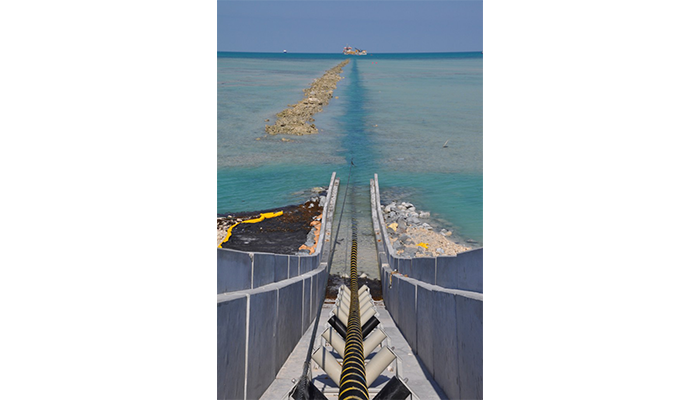

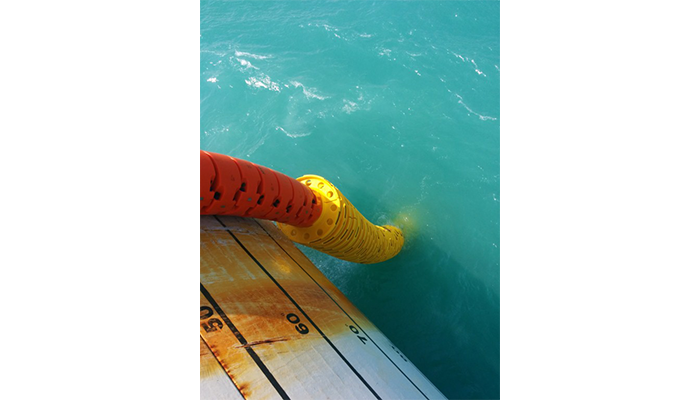

Our scope of work involved project management, installation analysis, OHVS pull-in analysis, beach pull-in analysis, vessel operability analysis, project engineering, beach pull-in and design & provision of equipment.

CABLE CROSSING THE PERSIAN GULF

maximum of 200 megawatts electricity from Ras Laffan Industrial City through a subsea cable. Halul Island (100km northeast of Doha, the capital of Qatar) will have two 100km-long 132kV subsea cables for efficient electric power supply from Ras Laffan Industrial City (80km from Doha). The 132kV cable comprises 3 core power cables with embedded fibre optic cables to transmit 100MW power in total.

LARSoffshore was involved with the subsea power cable. Our scope of work involved project management, installation analysis, crossing protection analysis, joint deployment analysis, beach pull-in analysis and project engineering.